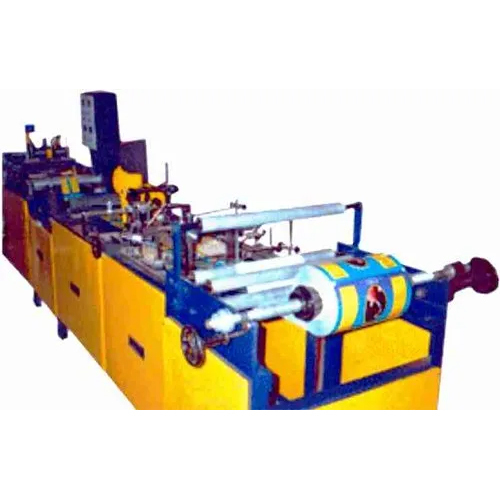

Medical Pouch Making Machine

Product Details:

- Power Source Pneumatic

- Operating Type Automatic

- Power 5 Horsepower (HP)

- Pressure 1 to 10 Bar

- Dimension (L*W*H) 15*6*5 Foot (ft)

- Weight (kg) 600 Kilograms (kg)

- Warranty 12 months

- Click to View more

Medical Pouch Making Machine Price And Quantity

- 1 Set

- 900000 INR/Set

Medical Pouch Making Machine Product Specifications

- 5 Horsepower (HP)

- 15*6*5 Foot (ft)

- 600 Kilograms (kg)

- 12 months

- Pneumatic

- Automatic

- 1 to 10 Bar

Medical Pouch Making Machine Trade Information

- wooden crate

- All India

- CE

Product Description

TYPE:Three side seal {with two webs} pouch or Two side seal rolls making machine.

Unwind 1:To hold 500 mm width material. (Paper), Min. 50 mm, 460 mm Dia. Max. 76 MM core ID. Powder Brake 5 Nm with controller

Unwind 2:To hold 500 mm width material. (Tyvek), Min. 50 mm 460 mm Dia. Max. 76 MM core ID. Powder Brake 5 Nm with controller

MAIN FRAME:Fabricated on 75X40mm MS Chanel. Heavy construction made, vibration less to suit 100-p/min pouching speed.

PUNCHING UNIT:One 'D' Punch unit to punch a hole with movement connected through pneumatic piston for up and down motion. Pressure controlled through pneumatic control. Time controlled through PLC.

SIDE SEALER (L) & (R):2 units for left and Right side provided with movement connected through pneumatic piston for up and down motion. Pressure controlled through pneumatic control. Time controlled through PLC.Winding unit:A tension controlled winding unit provided for winding of 2 side sealed rolls.

Flexo Unit: To print indicator ink mark in continuous printing.

CHEVRON SEALER: Chevron shaped sealing die unit with movement connected through pneumatic piston for up and down motion. Pressure controlled through pneumatic control. Time controlled through PLC. Quotation includes only 1 pcs of Die. Extra Die sealer will be Rs. 6000/- per pc, extra.

PHOTO CELL:An electronic eye to control the driving servo motor for print or punch registration.

CUTTING BLADE:Cutting Blade (22") movement connected through pneumatic piston for to and fro motion. Pressure controlled through pneumatic control. Time controlled through PLC.

PRESSURE ROLLS: Rubber rolls pneumatically operated and controlled. All IDLERS: Idlers of Aluminum Seamless pipe by machine.

CONTROL PANEL: Suitable for A.C. drives & Servo drive with microprocessor.COUNTER: Counter to give buzzer after 100 PCs. & integrator total counter.TOTAL ELECTRIC LOAD: 1.5 KW Drive power. 3 K.W. Heating Load.